Supported by more than 30 patents, which is DEELEE's advantage field. Now more than 60 well-known furniture companies are using DEELEE solution for kitchen cabinet door's production.

DEELEE CNC independently develops software docking and can provide automated production solutions according to customer needs.

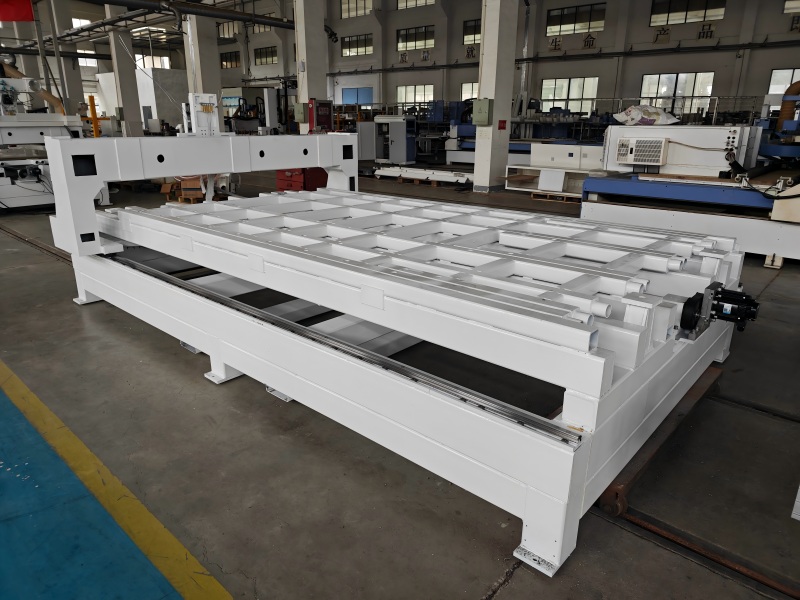

Machine can be used in the production of panel furniture's processing, nesting, drilling and 3D engraving. It's usually applied to cabinet furniture and kitchen cabinet door's production.

Take a look at our round up of the best shows

Take a look at our round up of the best shows

It has survived not only five centuries

It has survived not only five centuries

Lorem Ipsum has been the ndustry standard dummy text

Lorem Ipsum has been the ndustry standard dummy text

Jan 30, 2026

Jan 30, 2026